Supply chain transparency isn’t a buzzword anymore. It’s the baseline for doing business. For chemical suppliers, that means adopting green supply chain strategies is mandatory. Customers, regulators, and even employees expect it.

In this guide, we’ll break down proven methods that chemical companies can use to make their operations more sustainable.

What Is a Green Supply Chain in the Chemical Industry?

Green supply chains focus on protecting the environment in every part of business. The goal is to lower carbon emissions, reduce waste, and use resources more wisely.

This is especially important for chemical companies, since they depend heavily on fossil fuels and their products can harm the environment.

Building a sustainable supply chain means treating safety, security, resilience, and responsibility as equally important as profit and product quality.

Digital tools now make this much easier.

For example, digital SDS management systems like “SDS Manager” can provide instant access to chemical safety information. They also help companies follow regulations and keep track of dangerous materials throughout their supply chain.

The Business Case for Green Supply Chains

Building sustainable supply chains offers companies clear, measurable benefits such as:

- Lower Costs: Using energy more efficiently and cutting back on waste directly leads to smaller bills. By getting rid of unnecessary steps and recycling materials, companies save money over time.

- Fewer Problems: Staying ahead of environmental regulations helps businesses avoid fines, project delays, and legal issues. It’s always cheaper to be prepared than to deal with a mess later.

- Bigger Customer Base: More and more large customers prefer to partner with suppliers who meet certain environmental standards. Going green can open up brand-new markets.

- New Ideas and Growth: Focusing on sustainable practices often leads to fresh thinking, better materials, and cleaner ways of doing things that help a company stand out.

- Attracting and Keeping Talent: A lot of today’s young professionals want to work for companies that are serious about the environment. Being environmentally responsible makes a business a more attractive place to work.

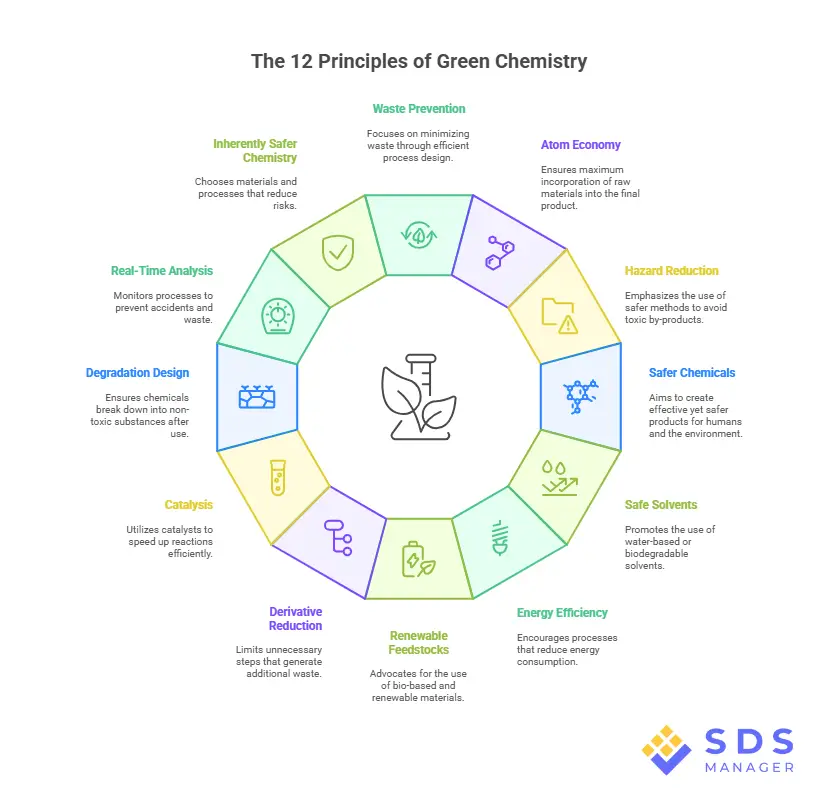

12 Principles of Green Chemistry Every Supplier Should Know

Paul Anastas and John Warner developed the 12 Principles of Green Chemistry as a practical guide to safer, smarter, and more sustainable practices.

The principles can be applied to procurement, production, transport, and customer relationships:

- Prevention – Avoid waste from the start by designing processes that produce less in the first place.

- Atom Economy – Ensure that most of the raw materials actually become part of the final product, not by-products.

- Less Hazardous Synthesis – Use safer production methods that limit harmful side effects and toxic residues.

- Designing Safer Chemicals – Create chemicals that do their job effectively but pose fewer risks to people and nature.

- Safer Solvents and Auxiliaries – Favor water-based or biodegradable solvents instead of harmful, toxic ones.

- Energy Efficiency – Cut energy use by relying on processes that work at normal temperature and pressure whenever possible.

- Use of Renewable Feedstocks – Use renewable raw materials, such as plant-based inputs, instead of fossil fuel–based ones.

- Reduce Derivatives – Eliminate unnecessary steps that create extra waste or require additional chemicals.

- Catalysis – Use catalysts to speed up reactions more efficiently, saving resources and energy.

- Design for Degradation – Build products that naturally and safely break down into harmless substances once their use is finished.

- Real-Time Analysis – Use tracking tools to keep an eye on processes as they happen, preventing accidents and catching waste early.

- Inherently Safer Chemistry – Select materials and processes that reduce the chance of accidents such as fires, spills, or explosions.

When suppliers follow these principles, they can meet their sustainability goals and what the law and their customers expect.

Core Green Supply Chain Strategies for Chemical Companies

Sustainable Sourcing of Raw Materials

Green supply chains start with responsible sourcing. Companies now evaluate suppliers on environmental practices as well as cost and quality.

- Bio-based raw materials can reduce reliance on petroleum.

- Local and regional sourcing cuts transport emissions.

- Supplier audits often include environmental standards and sustainability reporting.

Circular Economy and Advanced Recycling

The circular economy keeps materials in use rather than discarding them. Chemical companies are leading this shift by:

- Using advanced recycling to turn used plastics into new, high-quality materials.

- Designing products that are easier to recycle.

- Creating programs that turn waste into valuable new products.

Energy Efficiency and Renewable Energy Adoption

Chemical plants use large amounts of energy. Improving efficiency and adopting renewable energy makes a big difference.

- Process optimization and AI tools help reduce energy waste.

- Facilities are increasingly using solar, wind, or recovered heat.

- Energy storage systems improve the reliability of renewable power.

Greener Transportation and Logistics

Transporting chemicals adds to emissions. Companies can:

- Shift more shipments to rail or water where possible.

- Use route optimization software to cut fuel use.

- Adopt electric trucks, hydrogen fuel, or biofuels.

- Share logistics networks with partners to save resources.

Staying Compliant with Environmental Regulations

U.S. suppliers have to follow regulations set by EPA and OSHA, as well as global standards like ISO 14001. New regulations are pushing for more transparency about a company’s impact on the climate and a product’s entire life from start to finish. To stay ahead of the curve, companies need to manage their data well and perform regular checks.

Measuring Sustainability Progress in Supply Chains

Common metrics to measure and improve include:

- Carbon footprint and greenhouse gas emissions.

- Water use and quality.

- Waste recycling and diversion rates.

- Energy efficiency per unit of production.

Collaboration and Partnerships for Greener Supply Chains

Green supply chains depend on cooperation. Suppliers often work with:

- Customers to design safer, more sustainable products.

- Industry groups to share best practices.

- Universities for research into new green technologies.

- Government programs for funding and regulatory support.

Conclusion

Green supply chain strategies in the chemical industry focus on finding smarter, safer, and more efficient ways to operate. For this to work, everyone in the company must be on board.

Leadership needs to set the tone and provide the necessary tools and support.

Employees should receive the right training to follow safer, greener practices in their daily work.

Finally, a sustainable supply chain depends on close cooperation with both suppliers and customers. It’s a team effort that extends far beyond the factory gates.

Anamika is a passionate writer for Eco365Store.com, specializing in topics that inspire a cleaner, greener world. With expertise in home cleaning, recycling, and eco-friendly solutions, she crafts engaging and informative articles that help readers adopt sustainable practices in their daily lives.